How Electromagnetic Testing Works: Basic Principles

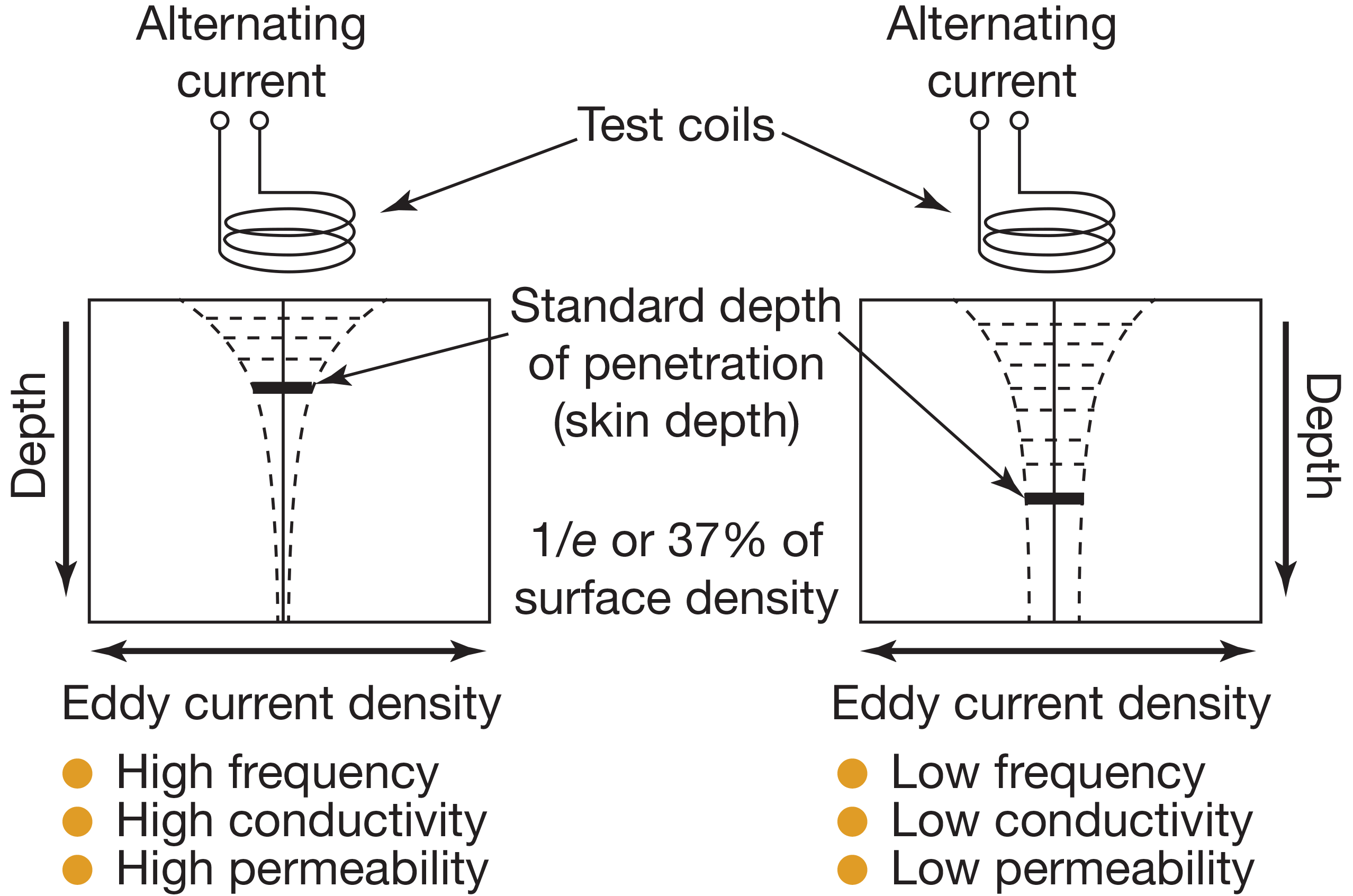

In the ET method, alternating current (AC) is applied to a coil, creating a varying electromagnetic field. Technicians place an eddy current probe, which can be a coil encircling the material or a handheld probe moved across the surface, on the material and the electromagnetic field can penetrate the material directly.

The probe generates an alternating magnetic field, which induces eddy currents in the conductive material being inspected. These eddy currents create their own secondary magnetic field, which opposes the primary field generated by the probe.

When eddy currents encounter a discontinuity—a material with different electrical conductivity or magnetic permeability—they are disrupted, causing changes in the secondary magnetic field. By analyzing these changes, skilled operators can determine the presence and characteristics of discontinuities, such as cracks, corrosion, or inclusions.

NDT practitioners leverage a comprehensive understanding of various probe types, frequencies, and display options, enabling the ET method to be flexible across many kinds of requirements, environments, and applications.

)