How Ultrasonic Testing Works: Basic Principles

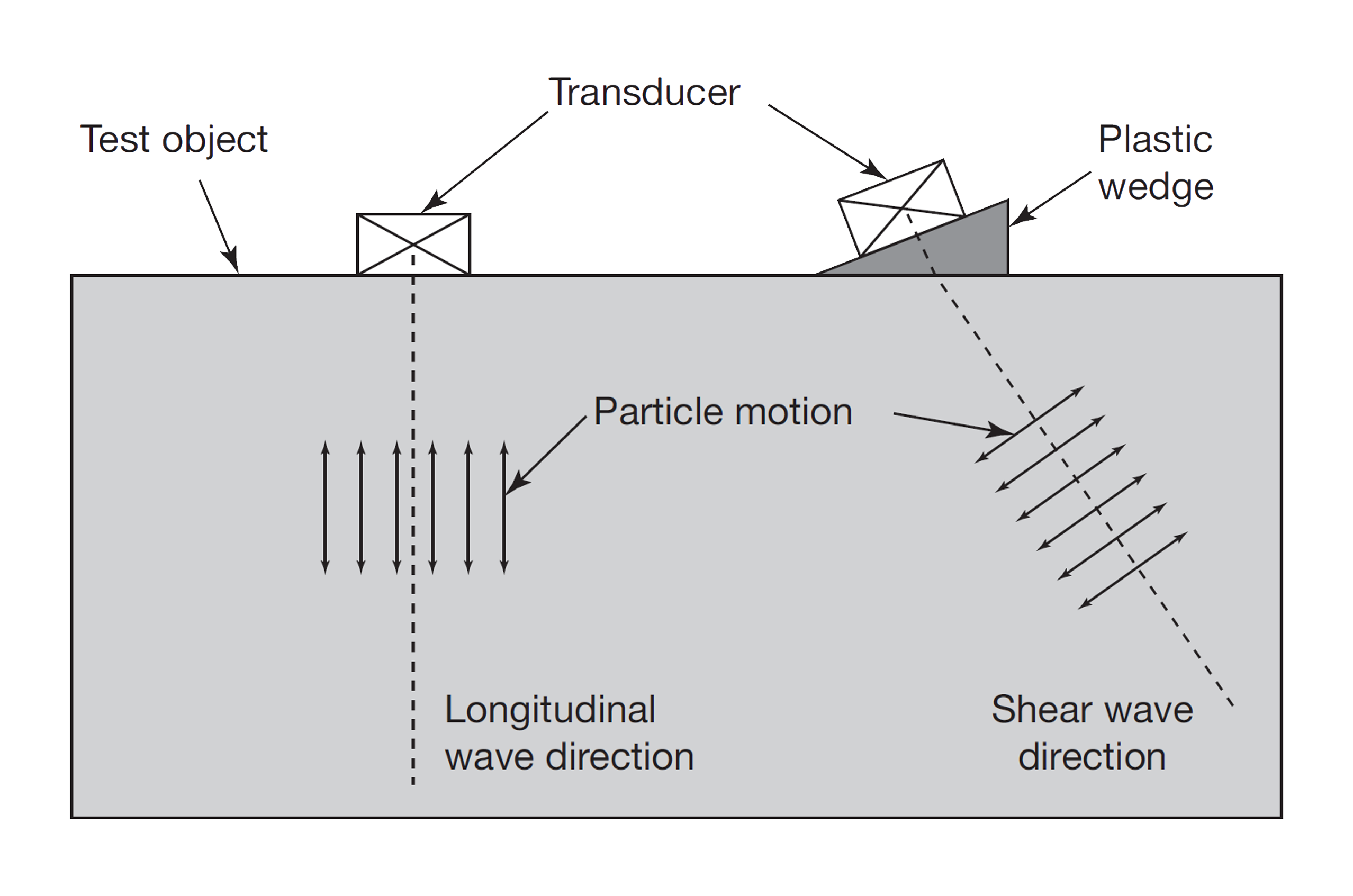

In the UT method, ultra-high-frequency sound waves are introduced into the part being inspected. Technicians place an ultrasound transducer (or probe) on the material, typically with a layer of liquid or gel called couplant to facilitate sound wave transmission into the part.

The transducer converts electrical impulses into sound waves, then converts returning sound back into electrical impulses that can be displayed visually on a screen.

When sound waves encounter a reflector—a material with different density and acoustic velocity—they bounce back to the transducer. By analyzing the time and amplitude of these echoes, skilled operators can determine the distance to the reflector and identify the type of discontinuity, such as slag, porosity, or cracks in a weld.

NDT practitioners leverage a comprehensive understanding of various wave types, transducer types, and display options, enabling the UT method to be flexible across many kinds of requirements, environments, and applications.

)

)