Steps in the Visual Testing Process

1

Surface Preparation

Clean the surface to remove any contaminants that could obscure defects.

2

Inspection

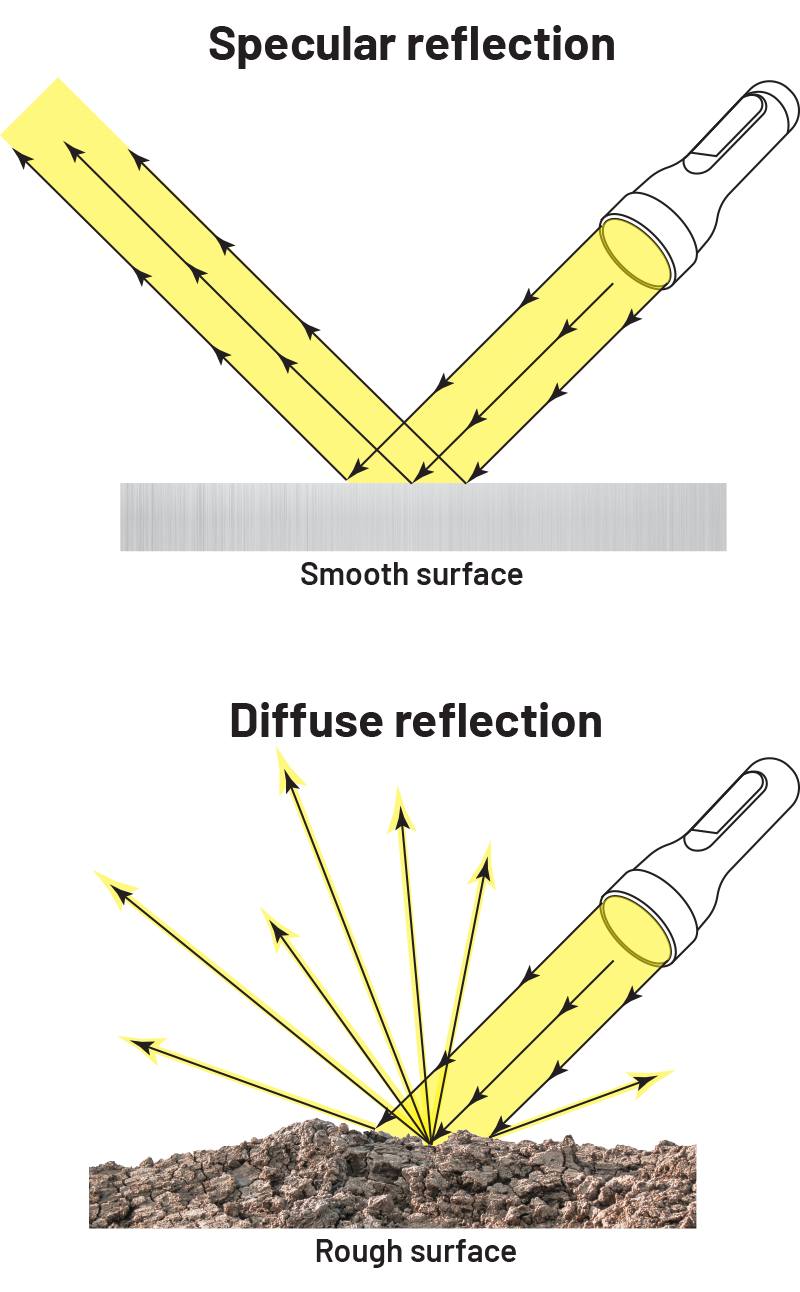

Use appropriate lighting and optical aids to examine the surface.

3

Evaluation

Identify and assess any discontinuities based on established criteria.

4

Reporting

Document the findings, including any discrepancies or defects identified.

)

)